Harish Projects

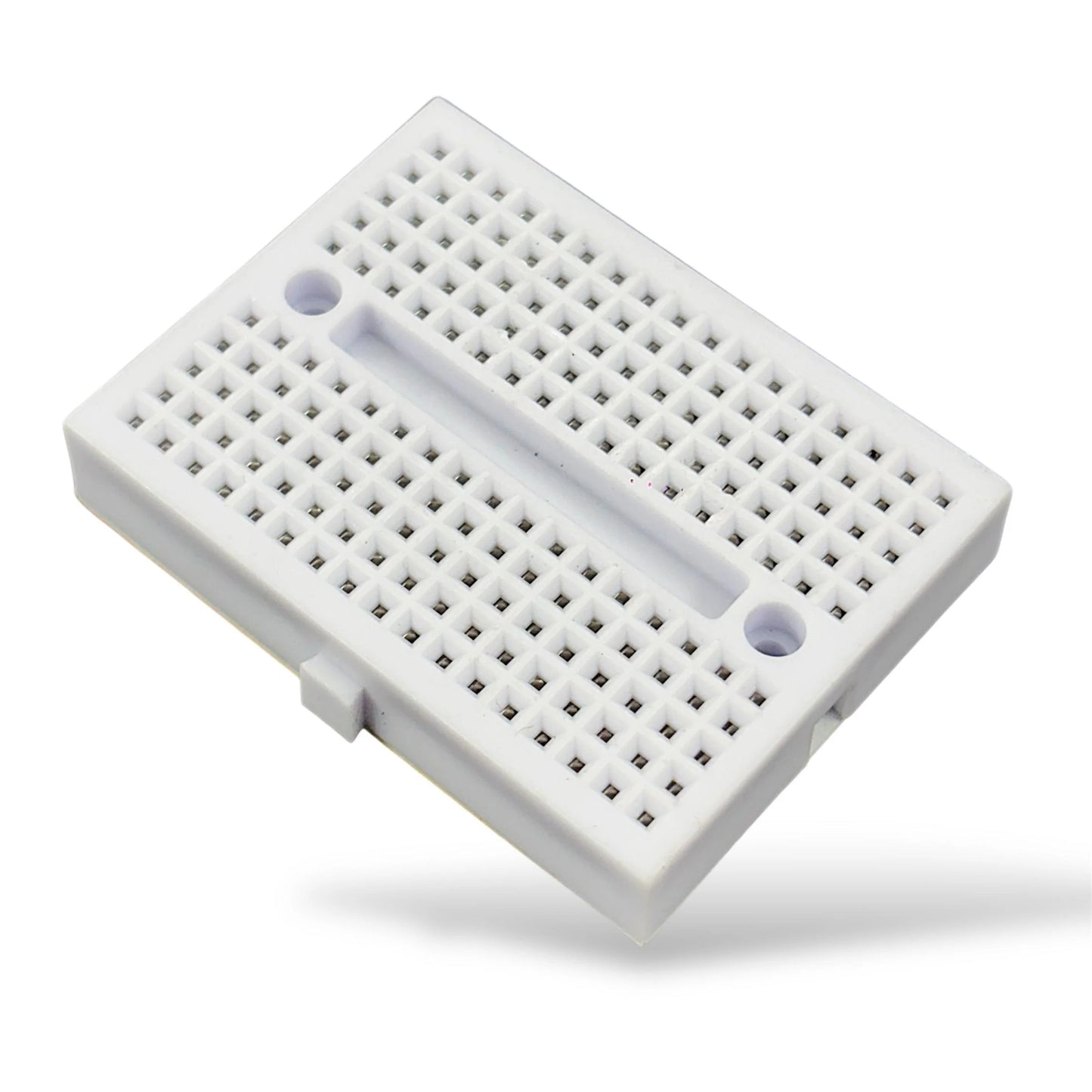

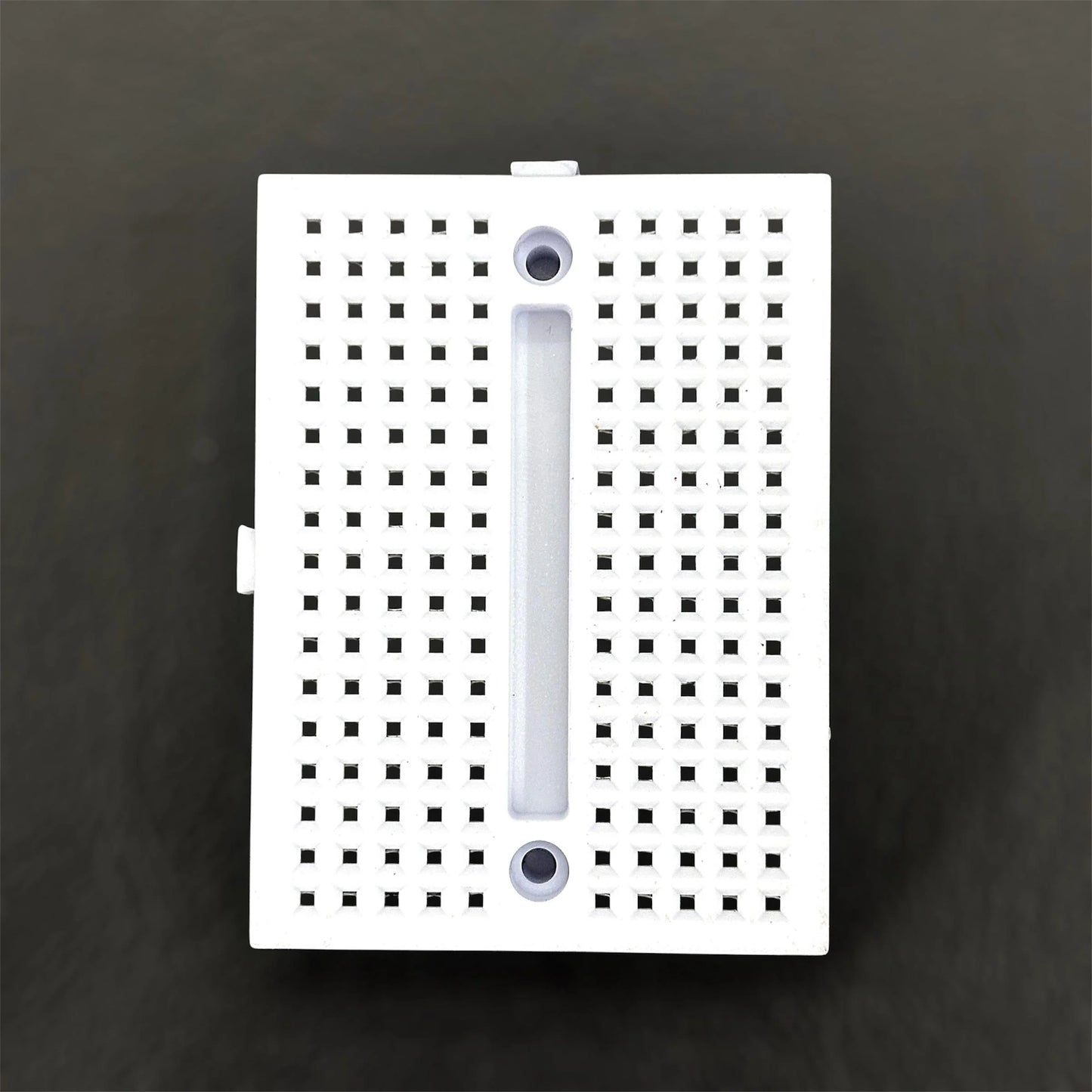

Small Breadboard Solderless 170 tie points

Small Breadboard Solderless 170 tie points

Couldn't load pickup availability

Share

Specification

- 170 tie points

- Small Circuit Projects

- Perfect for Arduino shield prototyping and testing

- Plastic housing, metal contact clips

Description

A small breadboard, also known as a solderless breadboard, is a common prototyping tool used in electronics to build and test circuits without the need for soldering. While the specific specifications may vary between different manufacturers and models, here are some typical specifications for a small breadboard:

1. Dimensions: Small breadboards are usually compact in size, typically measuring around 3.5 cm (1.4 inches) in width and 4.5 cm (1.8 inches) in length. These dimensions may vary slightly depending on the specific model.

2. Terminal Strips: Breadboards consist of multiple terminal strips arranged in a grid pattern. Each terminal strip usually consists of two or more rows of holes. The most common configuration is a terminal strip with two rows, where each row contains 5 or 10 holes. Some breadboards may have more rows or additional features, such as power rails, depending on the model.

3. Interconnectivity: The holes within each terminal strip are internally connected, both horizontally and vertically. This means that all holes in the same row are electrically connected, as well as all holes in the same column. However, there is typically no electrical connection between holes on different terminal strips.

4. Power Rails: Many small breadboards feature two power rails running alongside the terminal strips. These power rails are often colored differently (such as red and blue) to denote their purpose. The power rails provide convenient access to power and ground connections for components on the breadboard.

5. Hole Spacing: The holes on a breadboard are usually spaced at a standard pitch of 2.54 mm (0.1 inches). This spacing allows for compatibility with most electronic components, including integrated circuits (ICs) and dual-inline packages (DIPs).

6. Mounting: Small breadboards are often designed to be portable and used for temporary prototyping. They may feature adhesive backing or mounting holes that allow for secure placement on a flat surface or integration into larger projects.

7. Material: The base of the breadboard is typically made of plastic, providing electrical insulation between the terminal strips and preventing short circuits. The holes in the breadboard usually contain metal contacts to establish electrical connections.

It’s important to note that while these specifications are common, there can be variations among different small breadboards available in the market. Therefore, it’s always a good idea to check the specific specifications provided by the manufacturer or seller before making a purchase.

Superb quality nice material