1

/

of

4

Harish Projects

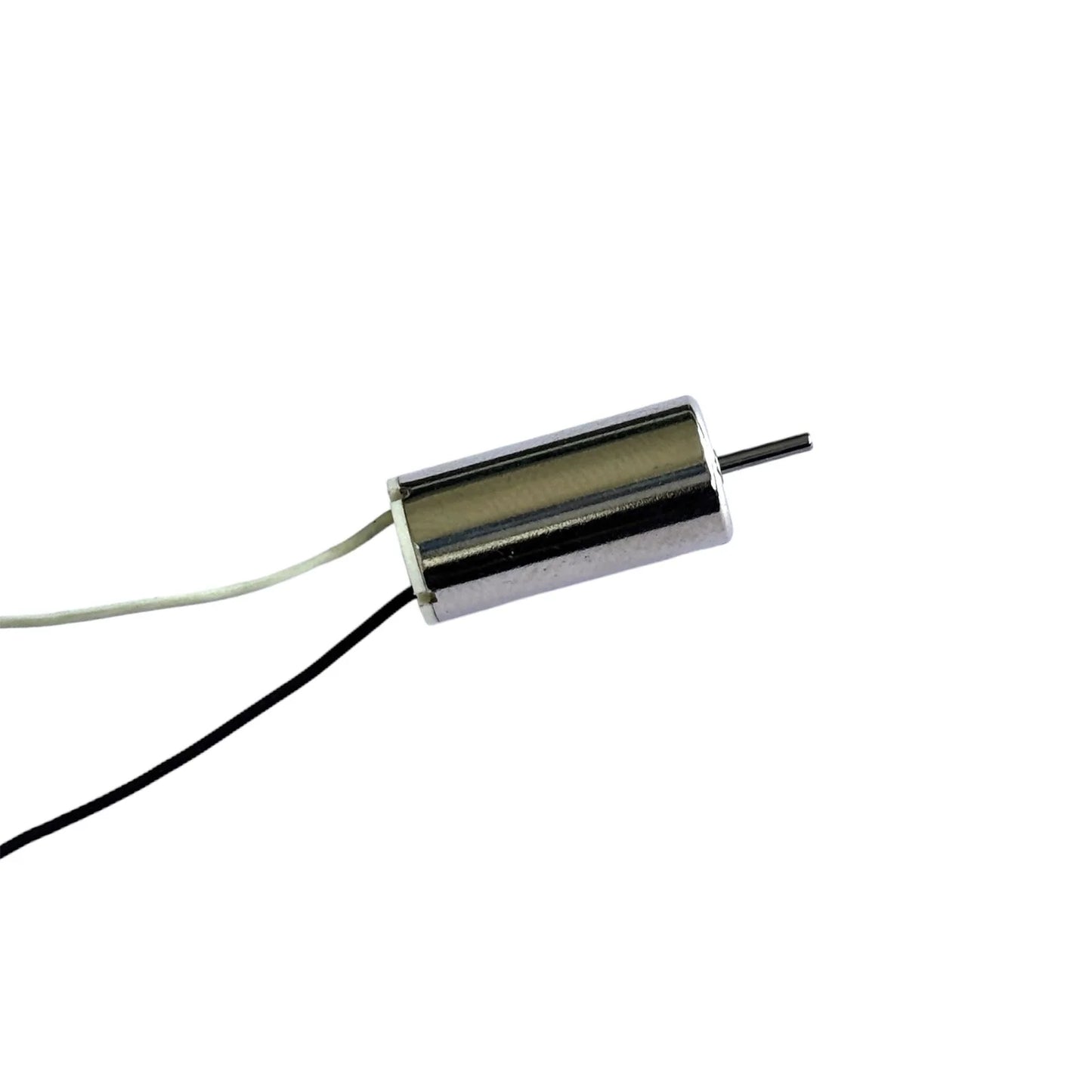

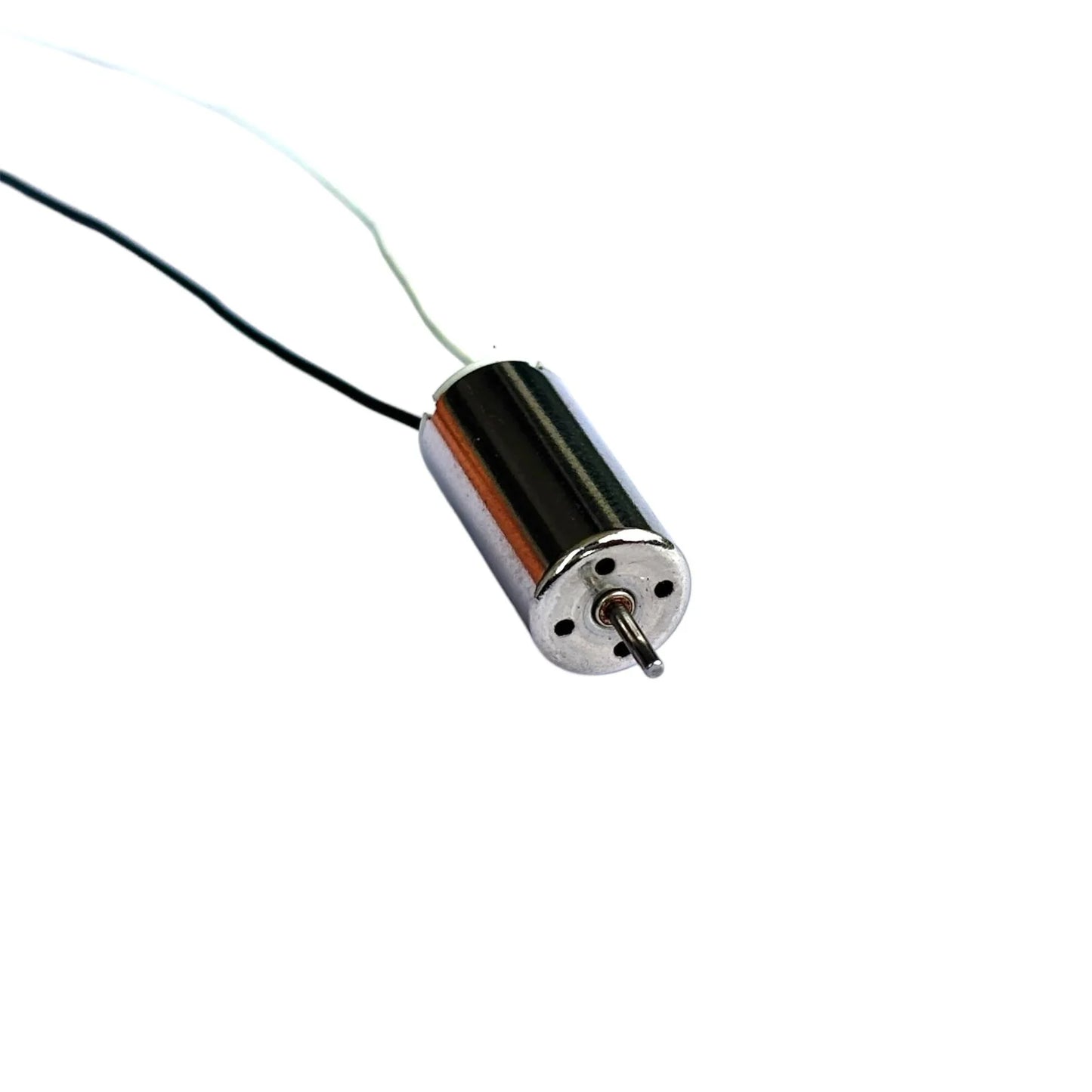

7mm Coreless Mini Drone Motor | 48000 RPM High-Speed Motor for RC Drones, DIY Projects & Robotics

7mm Coreless Mini Drone Motor | 48000 RPM High-Speed Motor for RC Drones, DIY Projects & Robotics

Regular price

Rs. 50.00

Regular price

Rs. 100.00

Sale price

Rs. 50.00

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

5 reviews

Share

Key Features

- Diameter: 7mm Coreless Motor (Size 17x7x7 mm)

- Speed: Up to 48,000 RPM

- Lightweight, compact & energy-efficient design

- Ideal for mini drones, quadcopters, robotics & DIY projects

- Durable motor with stable high-speed operation

Description

This 7mm high-speed coreless motor is an essential component for building or upgrading drones and small robotics projects.

Enhance your drone’s performance with this 7mm Coreless Mini Drone Motor. Designed for RC drones, quadcopters, robotics, toys, and DIY electronics, this motor delivers an impressive 48,000 RPM high-speed output in a compact and lightweight design. Perfect for hobbyists and makers, it ensures smooth, efficient, and reliable performance.

C

Cheeku Very good your product is good quality❤️🥰🥰🥰🥰🥰🥰🥰🥰🥰🥰🥰🥰🥰🥰🥰🫡🫡🫡🫡🫡🫡🫡🫡😙🥰🥰🥰

D

Debarun Deka This is a best I have ever seen

H

HEMANT KHATRI THANK YOU HARISH PROJECT

A

Anil Vishwakarma Good product 👌