1

/

of

2

Harish Projects

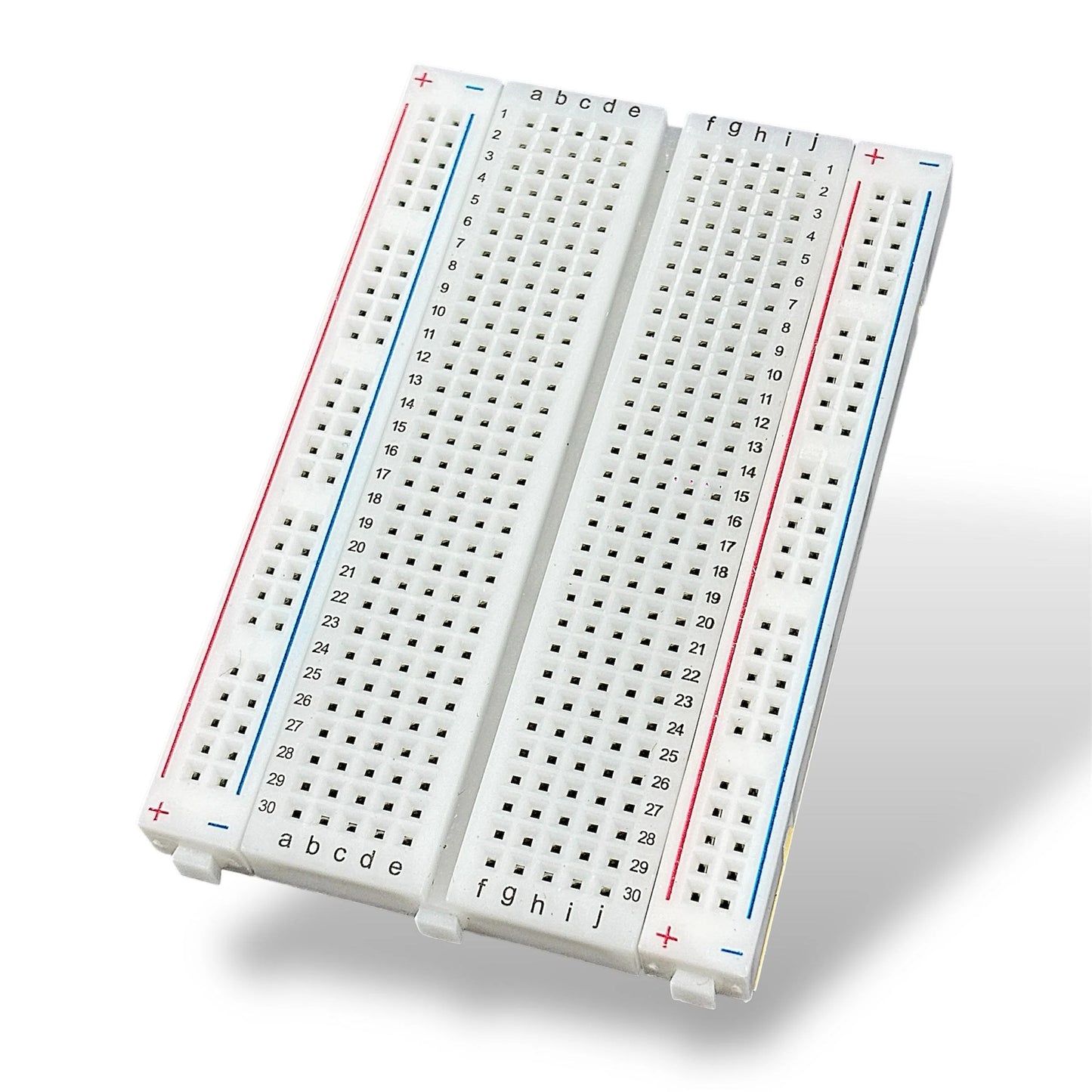

Medium Size Breadboard Solderless 400 Tie Points – Prototype Board for Electronics

Medium Size Breadboard Solderless 400 Tie Points – Prototype Board for Electronics

Regular price

Rs. 60.00

Regular price

Rs. 100.00

Sale price

Rs. 60.00

Taxes included.

Shipping calculated at checkout.

Quantity

Couldn't load pickup availability

4 reviews

Share

Technical Specifications

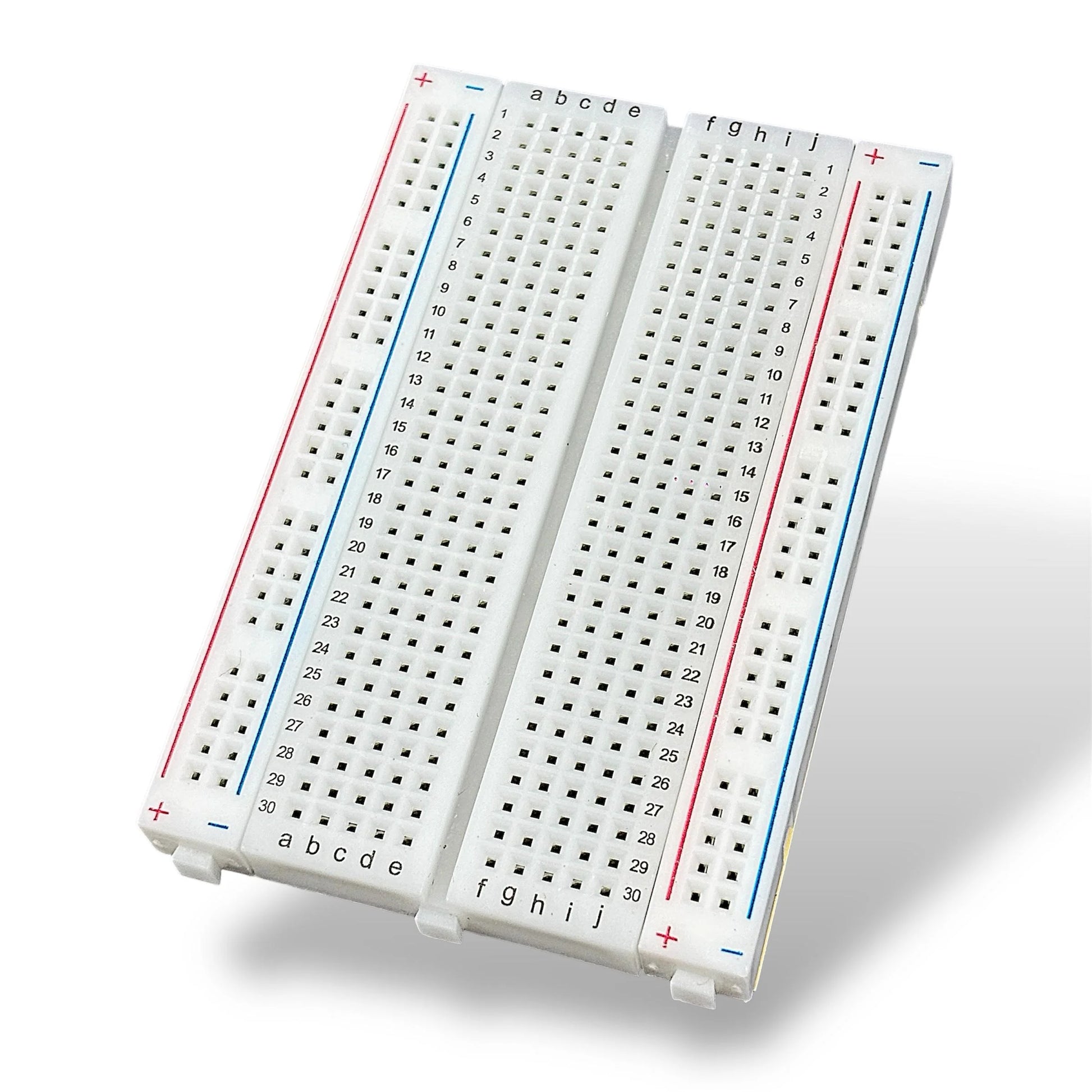

- Product Type: Solderless Breadboard

- Size Category: Medium

- Total Tie Points: 400

- Terminal Strips: 300 Tie Points

- Power Rails: 2 × 50 Tie Points

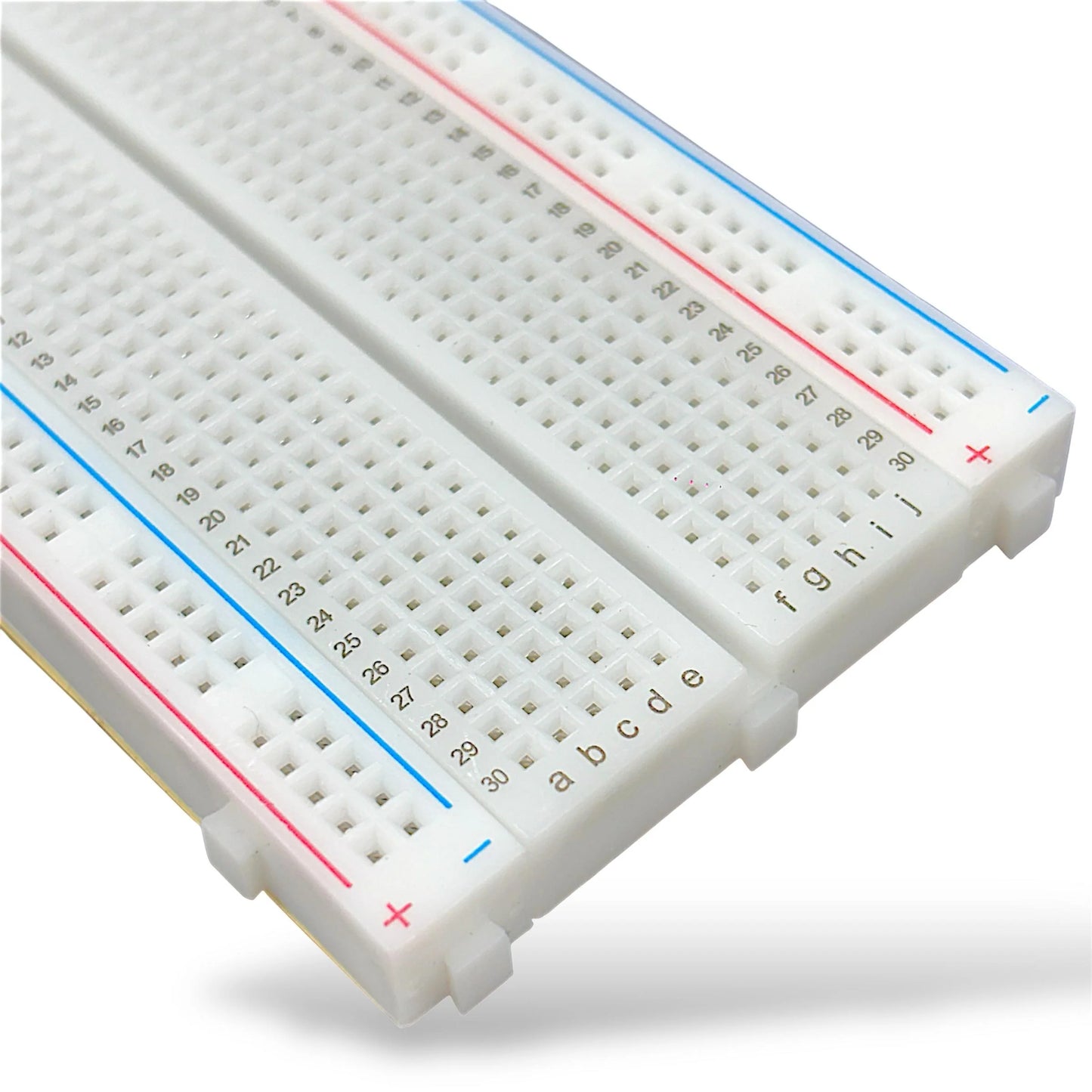

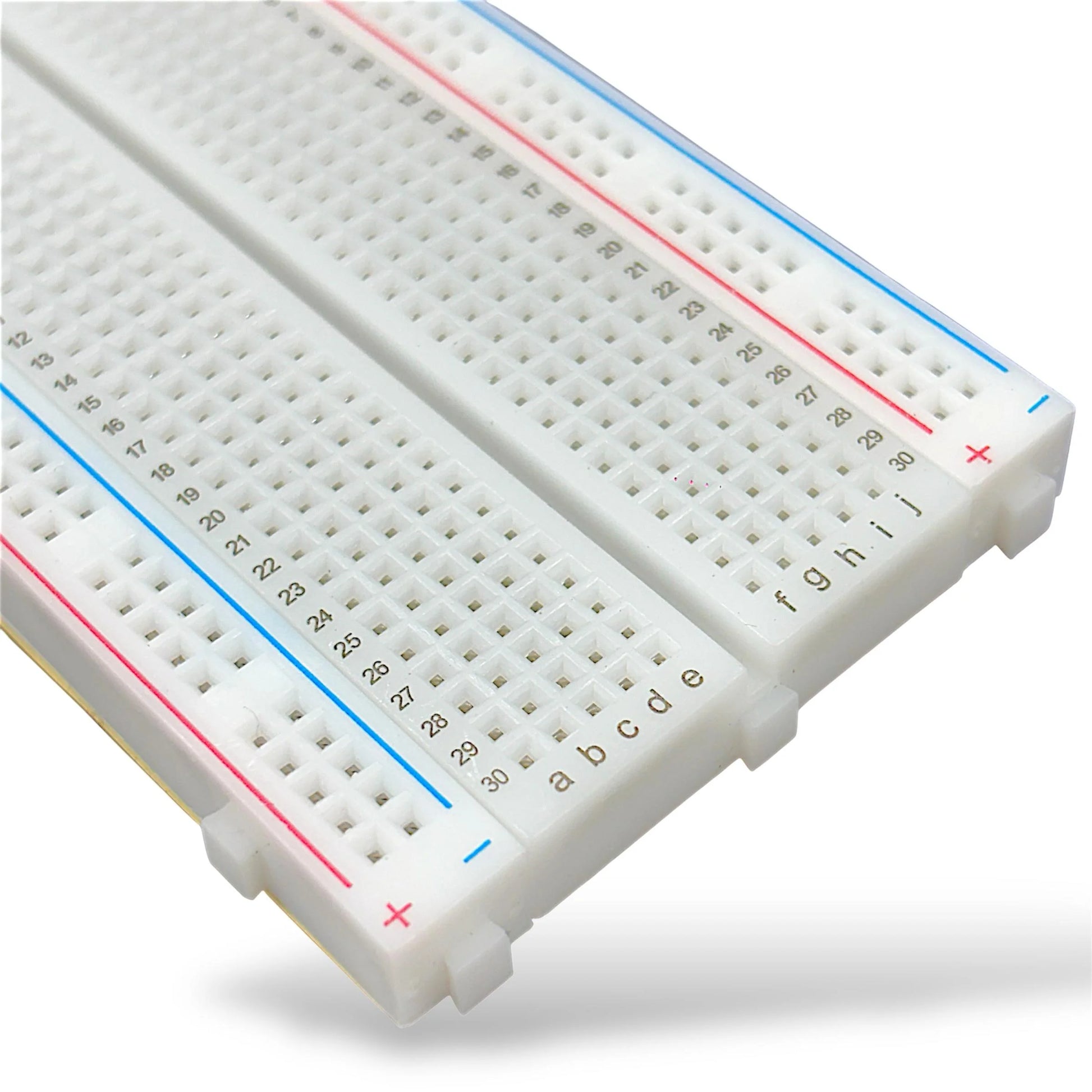

- Pitch: 2.54mm Standard

- Accepted Diameter: 20-29AWG

- Voltage/Current: 300V/3-5A

- Contact Material: Phosphor Bronze with Nickel Plating

- Backing: Adhesive Tape (Peel & Stick)

- Reusability: Yes (Solderless Design)

- Compatible With: Arduino, Raspberry Pi, ICs, Sensors

- Application: Prototyping, Testing, Education, DIY Electronics

Product Description

The Medium Size Solderless Breadboard with 400 tie points is an essential tool for electronics prototyping and circuit testing. It allows quick and easy connections without soldering, making it ideal for students, hobbyists, and professionals working on Arduino, Raspberry Pi, and other microcontroller-based projects.

Designed with standard 2.54mm pitch, this breadboard supports ICs, resistors, capacitors, and jumper wires securely. The strong internal contacts ensure reliable electrical connections, while the adhesive backing enables easy mounting on work surfaces or project enclosures. Perfect for learning, experimentation, and rapid development.