1

/

of

3

Harish Projects

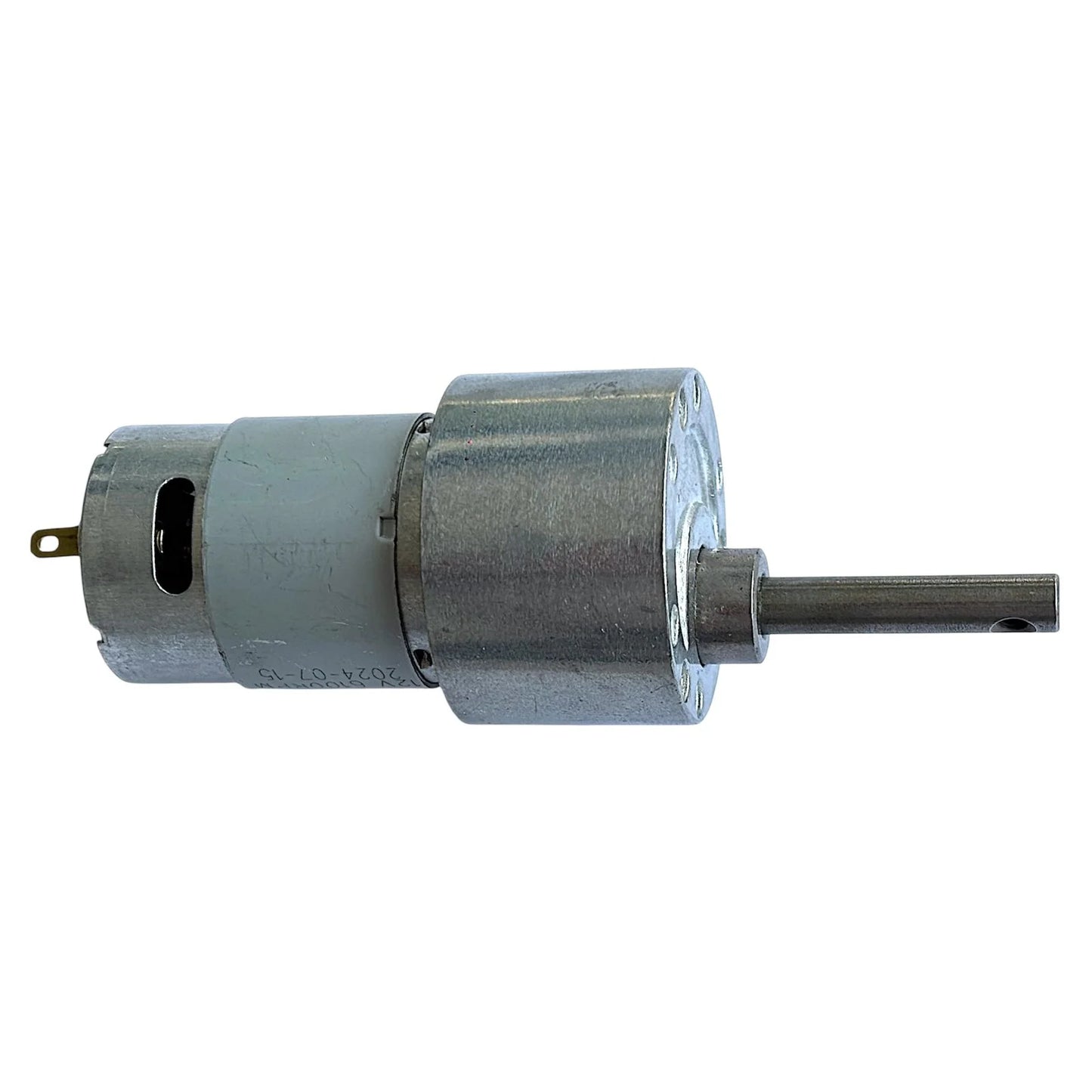

200 RPM Johnson Geared DC Motor 12V | Metal Geared Motor

200 RPM Johnson Geared DC Motor 12V | Metal Geared Motor

Regular price

Rs. 420.00

Regular price

Rs. 480.00

Sale price

Rs. 420.00

Unit price

/

per

Taxes included.

Shipping calculated at checkout.

Couldn't load pickup availability

1 review

Share

Specification

- Voltage Rating: 12V DC

- No-Load Speed: 200 RPM at 12V

Description

Boost your project's power with the 200 RPM Johnson Geared DC Motor 12V. This metal geared motor delivers efficient performance at a manageable 12V, making it perfect for a wide range of applications. With a 200 RPM speed, this motor provides reliable and precise power for your project.

G

Gunjan Chaudhary .